3D-printed school in Malawi: the benefits of disruptive technology

On the 21st of June 2021, the children of the Salima district of Malawi began attending classes in what is being referred to as the world’s first 3D-printed school.

Additive manufacturing, now commonly known as 3D printing, is becoming popular with small and large scale manufacturers. The technology is no longer as mysterious or futuristic as it seemed a few years ago. The school in Malawi is proof of the global spread of this disruptive technology. There is so much to look forward to with the challenges this technology can help accomplish in Africa.

UNDERSTANDING THE PROBLEM?

Malawi faces an estimated shortage of 36,000 classrooms, with a 78:1 ratio of pupils to qualified teachers at the primary level. Providing access to quality education in Malawi has been of utmost importance to the nation causing its government to allocate about 21.6% of its national budget towards the cause.

Advancement in technology as such could mean the beginning of the complete alleviation of the classroom shortage evident in Malawi. Expressing approval of the quality of 14Trees project on the Salima school structure, Primary Education Advisor, Juliana Kuphanga Chikandila representing Malawi’s Minister of Education, Youth and Sport, said she was impressed with the new building – that its durability and style would provide the space and facilities which students didn't have before. Stating also that the school would attract more students and prompt others who left to return to education.

WHAT IS 3D PRINTING AND HOW CAN IT HELP?

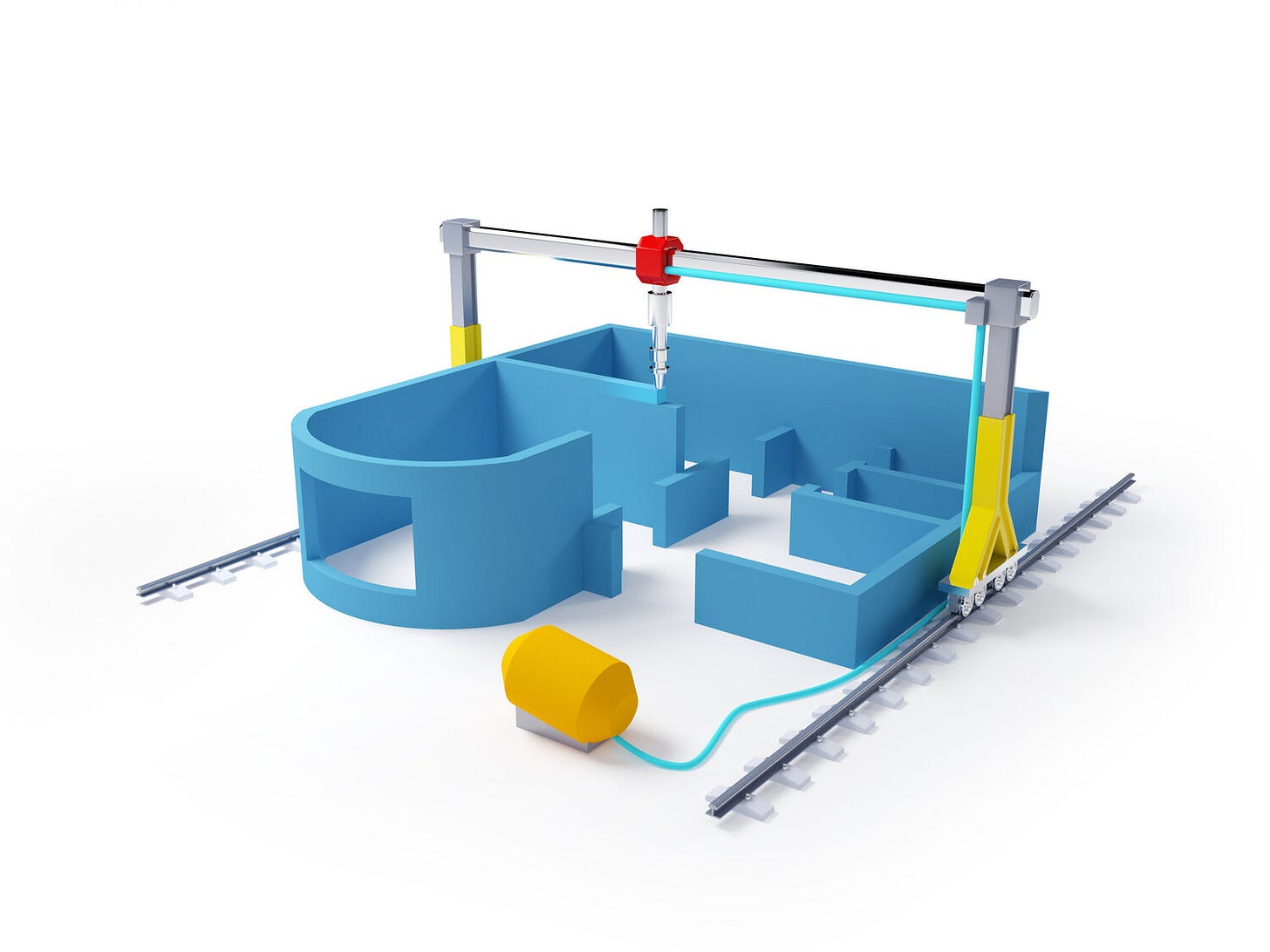

3D printing enables the production of complex shapes using less material than traditional manufacturing methods. 3D printing an object is achieved using additive processes. In an additive process, the object is created by laying down layers of material on top of each other until the object is created. The 3D printing machine prints layers based on a 3D model designed using computer software. The school in Salima is made of concrete layers.

Additionally, 3D printing also saves time. Francois Perrot, managing director for 14Trees says the use of this 3D printing technology, a speed in construction processes will be evident, reducing the time to build the needed classrooms to 10 years or even less, compared to the conventional construction methods which would take more than 70 years to build.

With the initiation of the 14Trees project, one crucial issue that will be taken care of is the apparent shortage of classrooms for the children, and in turn access to education. Another added advantage to the implementation of the 3D printed constructions is the job opportunities made available to the locals. Jobs such as roofing, carpentry, plumbing and electricity, can easily be outsourced to qualified citizens to also serve as means to wealth creation for locals.

One question to ponder however is the sustainability of this construction method. Malawi being identified as an underdeveloped country would have one wondering how they could afford these machines which are priced at $500,000. Other questions that have been raised have been directed towards ownership of said machines. Would the government purchase these machines or would they be owned by contractors or NGOs?

Nevertheless, the progress attained by the 14Trees group is remarkable. The emergence of this disruptive technology poses an undeniable breakthrough in construction, and with a vision to keep printing more schools, and houses in the long run one can only look forward to the milestones that would be achieved in Malawi by this project through the 14Trees project.